You Are Here - Products - Injection Blow Molding Machine

Cavity number of the mould corresponding to product dimension.(For reference)

| Diameter(mm) | 28 | 30 | 32 | 35 | 37 | 40 | 43 | 48 | 55 | 60 | 65 | 75 | 85 |

| Height(mm) | 50 | 52 | 55 | 60 | 70 | 85 | 90 | 90 | 90 | 95 | 100 | 105 | 110 |

| Central distance(mm) | 38 | 40 | 42 | 45 | 50 | 52 | 57 | 63 | 70 | 75 | 85 | 95 | 105 |

| Cavity | 18 | 17 | 16 | 15 | 14 | 13 | 12 | 11 | 10 | 9 | 8 | 7 | 6 |

SZCX 300/70X Main Technical Parameters

| Injection system | Unit | Parameter |

| Dia.of Screw | mm | 55 |

| Screw L/D | 24:1 | |

| Max Theoretical Shot Volume | cm3 | 400 |

| Injection Weight | g | 300 |

| Plasticing Capacity Approx | g/s | 60 |

| Max.Screw Stroke | mm | 170 |

| Max Screw Speed | rpm | 10~235 |

| Total Power for Charging Barrel | kw | 18.7 |

| No.of Heating Zone | Qty | 6 |

| Clamping System | ||

| Injection Clamping Force | kn | 705 |

| Blow Clamping Force | kn | 110 |

| Opening Stroke of Mould Platen | mm | 150 |

| Max Swing Radius | mm | 612 |

| Liftion Height of Rotary Table | mm | 75 |

| Max Platen Size of Mould (L×W) | mm | 780×460 |

| Min Mould Thickness | mm | 254 |

| Mould Heating Power | kw | 5.6 |

| Stripping System | ||

| Stripping Stroke | mm | 255 |

| Dry Cycle Time | s | 2.9 |

| Driving System | ||

| Motor Power | kw | 26.7+12 |

| Hydraulic Working Pressure | Mpa | 14 |

| Product Dimension Range | ||

| Range of Formability Product | ml | 2-1000 |

| Height of Formability Product | mm | ≤250 |

| Dia.of Formability Product | mm | ≤100 |

| Other | ||

| Compressed Air Pressure | Mpa | 0.7~0.9 |

| Compressed Air Discharge Rate | m3/min | 0.8 |

| Cooling Water Pressure | Mpa | 0.3~0.4 |

| Total Power | kw | 72 |

| Operating Power | 30~41% | |

| Overall dimension (L×W×H) | mm | 4830×1750×2200 |

| Machine Weight Approx | T | 10.5 |

Usage

This machine is one step 3station injection blow molding machine, it is suitable to make pharmaceutical, food, cosmetic bottles of many kind of material in PE、PP、PS、BAREX、PC、PVC.Operating Principle

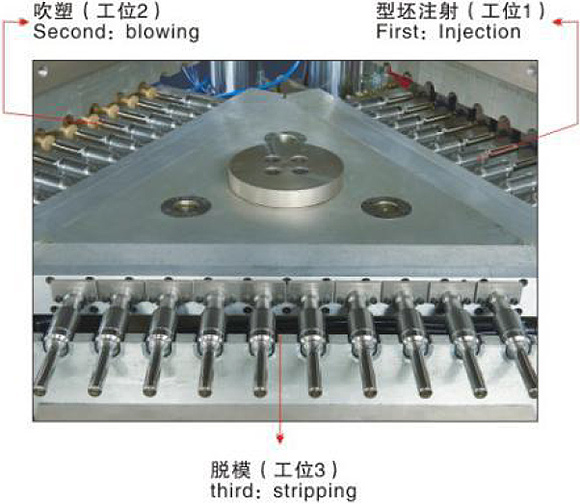

The core part of the one step injection blowing technics is a triangle-turnplate. The mandrils are assembled on the side face of the triangle-turnplate which roation is 120 degree.

▪ The First Service Position

The bottle neck will be molded accurately after injecting the material into the cavity. After proper control, the mold open and the mandrils turn to the second sevice postion along with the parison.▪ The Second Service Position

Blowing action was done at this cavity. Molding would be completed after cooling, (cavity of mold decide the shape and outward appearance of the bottle). The air came out from the mandrils expand the parison, making the parison cling to the mold. Then the mold open and the mandrils turn to the third service posita along with bottles.▪ The Third Service Position

The bottle automatically stripped from the mold at this position and then to packed through pipelining. The three actions of Injection, Blowing and stripping work at the same time, which makes the machine high output and energy saving.Characteristic

* Multicavity production.* Double proportional hydraulic control system.

* Three stations arranged at 120 degree, reduction of the cycle time, increase in production efficiency.

* Advanced and accurate PID temperature control system.

* Adopted hydraulic and pneumatic components of well-known brands from Germany and Japan.

* PLC control system of well-known brands and the whole machine operated easy and convenient.

* High utilization of raw material, high yield, high rate of return on investment.

* High precision in bottle neck and screw, best seaming.

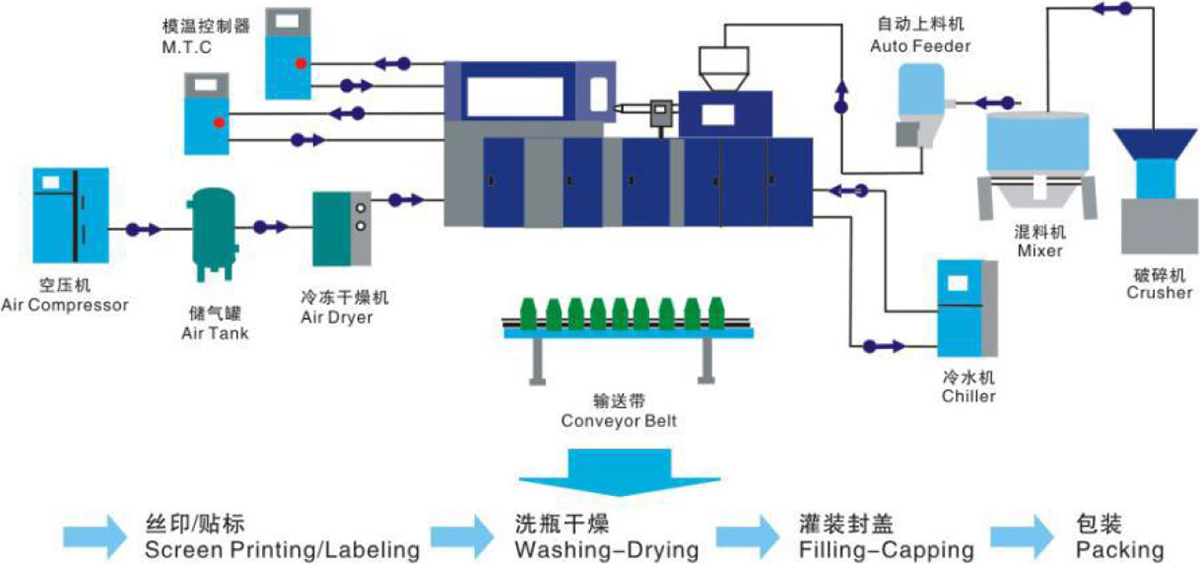

Production Line Components

The machine can manufactured acdording to the customers requirment

Keli is not produce machinery in batches, it will analyse the bottle shape, purpose, output and cost in order to make more suitable machine.Flawless customer service

Keli not to help customers to assemble the machine in their factory and train the worker but also offer before-sale, middle-sale and after-sale service, in order to develop new tchnology and products to satisfy the diversified need of market.The comparison of injection blowing and extrusion blowing

| Number | Injection Blowing | Extrusion Blowing |

| 1 | Bottle weight will change about 1% | Bottle weight will change about 3% |

| 2 | Uniformity wall thick | The change of wall thick is about 10-20% |

| 3 | None kerf | Not only has the kerf but also weaken the intension of the bottle bottom |

| 4 | Good convexity at the bottom of the bottle | Bad convexity at the bottom of the bottle |

| 5 | None flash | 20-40% flashes |

| 6 | Can not produce very thin thickness product | Can use equipment to adjust the thickness |

| 7 | Not sensitive to the enviroment change | Need more sdjustments during the production |

| 8 | Multicavity, high output smooth bottle neck | Less cavities, low output uneven bottle neck |

| 9 | High mould lifetime, suitable for long time production but high price | Short mold lifetime, suitable for short time production and low price |

| 10 | Compact machine system, less occupation of land | Need more assistant nachines, more occupation of land |

| 11 | Difflcult of ellipse plastic container | Easy |

The auxiliary equipments